Design files play a pivotal role in the production of vacuum forming molds and thermoforming molds. For vacuum forming molds manufacturers in China, handling these files with precision ensures that the final product meets the specifications for various applications. From custom designs to advanced tooling, understanding how design files are managed is key to delivering quality products. In this post, we explore how thermoforming molds suppliers in China process design files to create top-notch molds that meet industry demands.

Efficient File Formats and Digital Communication

One of the most critical steps in the process of producing custom vacuum forming molds is ensuring the design file is compatible with the manufacturing tools. Thermoforming tools manufacturers in China commonly work with digital files in formats like STEP, IGES, and STL, which are compatible with vacuum forming molding machines. These formats are widely used in vacuum forming molds China, as they ensure precision when translating the 3D design into a physical mold.

The communication between designers and manufacturers is streamlined by these digital formats, as they offer a highly accurate representation of the product design. A vacuum forming tools manufacturer often employs sophisticated software to convert 2D sketches or rough designs into 3D models, ensuring that all details are captured accurately. After receiving the design files, the manufacturer can provide feedback, ensuring that the mold can be produced with the required specifications, minimizing errors and reworks.

Use of 3D Printing for Prototyping

Many thermoforming molds manufacturers in China use 3D printing to prototype vacuum forming molds before committing to full-scale production. This method allows for a quicker turnaround and greater flexibility, especially when dealing with bespoken vacuum forming molds or designs that require adjustments. 3D print vacuum form molds are often created using high-quality materials that simulate the properties of the final product, allowing the team to identify any potential issues with the mold design before investing in traditional manufacturing.

The use of vacuum forming 3D printed molds offers a significant advantage in terms of time and cost. It enables manufacturers to test the mold’s fit, check for possible weak points, and fine-tune details. This iterative approach ensures that by the time the mold reaches the final stages of production, it’s perfectly aligned with the desired outcomes.

Collaboration and Design Adjustments for Customization

Collaboration is at the heart of how vacuum forming molds suppliers and customers interact, particularly when it comes to custom thermoforming molds. The process often involves several stages of feedback, where the design files are adjusted according to the manufacturer’s recommendations. Thermoforming tools and vacuum forming tools require high precision, and even minor changes to the design files can have a major impact on the final mold.

In China, vacuum forming molds China manufacturers typically work closely with their clients to ensure the design is fully optimized for production. This collaboration involves tweaking dimensions, material choice, and structural aspects to ensure that the mold performs under specific manufacturing conditions. The files are often revised multiple times during this phase to achieve the best possible result for the client’s product, whether it’s a small, intricate design or a large, industrial part.

Material Selection and Final Mold Production

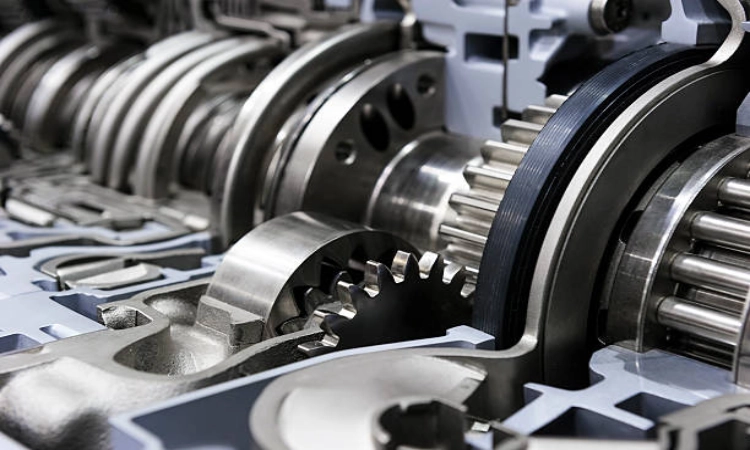

The final step in handling design files involves translating the 3D digital design into a mold that can be produced using vacuum forming molding machines and thermoforming molds. The design files directly influence the choice of vacuum forming mold materials such as ABS, PVC, HDPE, and PETG, which are selected based on the project’s requirements.

Thermoforming molds suppliers in China use the finalized digital files to create vacuum forming molds that can handle the intended production volume. The mold’s material must be capable of withstanding the thermal and mechanical stresses of the molding process. Advanced manufacturing techniques, such as CNC machining and casting, are used to ensure that the final mold is precise, durable, and capable of meeting the client’s specifications.

By the time the vacuum forming mold design is finalized and sent to production, the design files have been meticulously reviewed and tested, ensuring the mold’s quality and functionality.

Conclusion:

The management of design files in the creation of vacuum forming molds and thermoforming molds in China involves a careful balance of advanced technology, collaboration, and precision. From custom thermoforming molds to rapid prototyping with 3D print vacuum form molds, manufacturers ensure that the design is thoroughly tested before final production. This process allows for cost-effective, high-quality mold manufacturing, meeting the needs of industries ranging from automotive to medical packaging. Working with a reliable thermoforming molds manufacturer ensures that your designs are accurately brought to life with the precision and quality required for successful production.