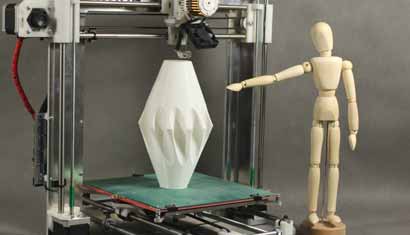

There are several factors you should consider when choosing a 3D printer. Automatic detection, materials used, and labor costs are just some of the important aspects to consider. Having a clear budget for your 3D printer is essential as well. Listed below are some tips to help you choose the right machine for your needs. Keep reading to learn more! Read on! Posted in 3D Printers, Factors to Consider When Choosing a 3D Printer

Automatic detection

One of the things to consider when selecting a 3D printer is whether or not it supports automatic detection. While many 3D printers come with built-in fault detection, some businesses may want to turn this feature off to protect their products. Automatic Detection pauses printing when the door or lid is opened. The accuracy of this feature is important when working with sensitive materials. The more accurate detection, the lower the risk of false negatives.

The automatic fault detection feature should be low-cost, withstand ambient conditions, and detect millimeter-scale geometric defects. The MTouch sensor is one such system. It uses an actuated contact sensor to detect the presence or absence of a print in certain places. The MTouch sensor can detect a variety of defects, including layer shift, interlayer bonding, and filament runout. The MTouch system is a popular option, and can detect defects as small as one micrometer.

Materials used

When a 3D printer is a useful tool, materials play a major role. Plastics offer the largest variety of 3D printing materials, and most commonly used are polyethylene terephthalate (PET), polyethylene glycol (PEG), Nylon, and polyetherimide. Some materials require post-processing or curing to achieve the desired end result, reducing the lead time by weeks. Polypropylene, for example, is an excellent material for 3D printing because it has good chemical resistance and is inexpensive. Also known as PEEK, this material offers the advantages of high-impact resistance and low-temperature tolerance, which make it ideal for parts that need to be impact-resistant. Unlike ABS, polycarbonate is lightweight and highly impact-resistant, making it an interesting material for printers that require stiffness and rigidity.

Polycarbonate is a great material for 3D printing but is susceptible to warping. To prevent warping, make sure to use a closed printer and set the temperature at a low level. Also, remember that high temperatures can cause the filament to deform and jam. Polyvinyl alcohol is a water-soluble support material. This material is ideal for printing complex geometries and difficult-to-remove support structures.

Labor costs

Consider labor costs when selecting a 3D printer. These costs include material costs, time spent on the preparation and printing process, and failure insurance. Additionally, the labor cost of operating the machine is another factor to consider. In addition to material costs, 3D printers also require operators to assemble and disassemble printed parts. Some models also require support structures and use mineral oil or isopropyl alcohol. All of these factors can add up to significant labor costs, Check out the post right here.

The first thing to consider when determining the cost of running a 3D printer is the cost of labor. Human labor can cost you dozens or even hundreds of dollars for a new design. Even if the model is simple, it can take many hours to draw and produce. Labor costs also depend on the type of parts that are printed. Larger objects and complex designs require higher amounts of filament and therefore more labor.

Budgeting

When purchasing a 3D printer, you will have two separate budgets: one for the actual 3D printer itself, and the other for the yearly functionality and maintenance of the printer. Many businesses make the mistake of spending the entire budget on the actual printer itself. This can lead to unexpected expenses in the form of consumables such as filament, and machine parts that wear out after a certain number of hours. In addition, if you want to produce metal parts, you’ll need to spend more money on sandblasting and oven heat treatments.

Conclusion:

As mentioned, a $3000-$500 3D printer may also require a $20,000-$50,000 service contract. The cost of an annual contract can vary according to the complexity of the machine and its reliability. Some businesses opt to purchase replacement parts at a higher price to avoid a service contract. If you’re on a strict budget, a $5-$10K budget should be sufficient for a high-quality 3D printer. However, if you plan on using the machine for high-demand tasks, you will have to budget more than this.